The end result of more playing around with the plastic LED

collimaters: they're not going to work well. Dang.

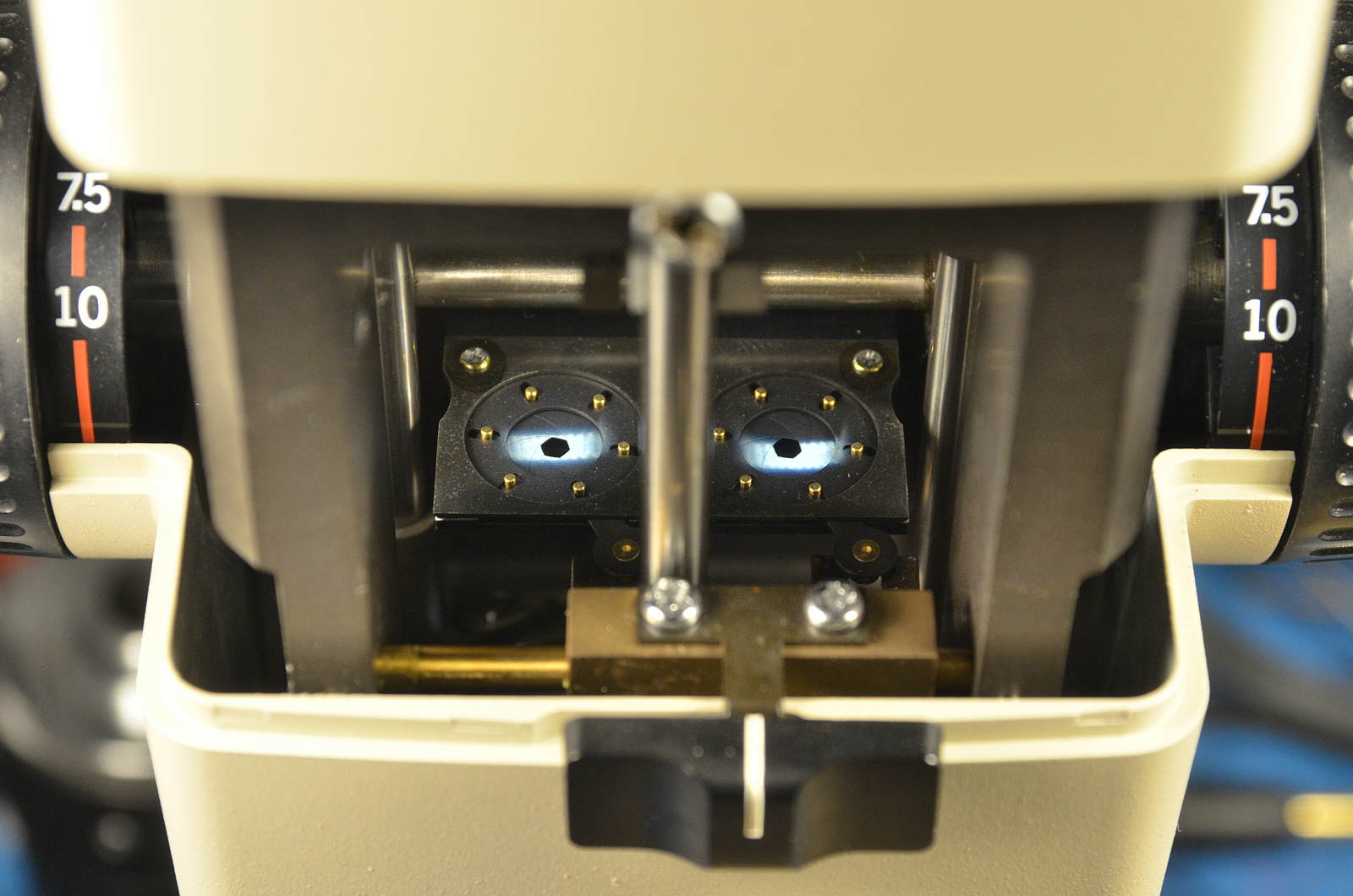

The microscope wants a small diameter parallel light beam, and the

plastic collimaters just won't do that. Even the tight spots

overfocus and overmagnify, and there's no real room for adjustment.

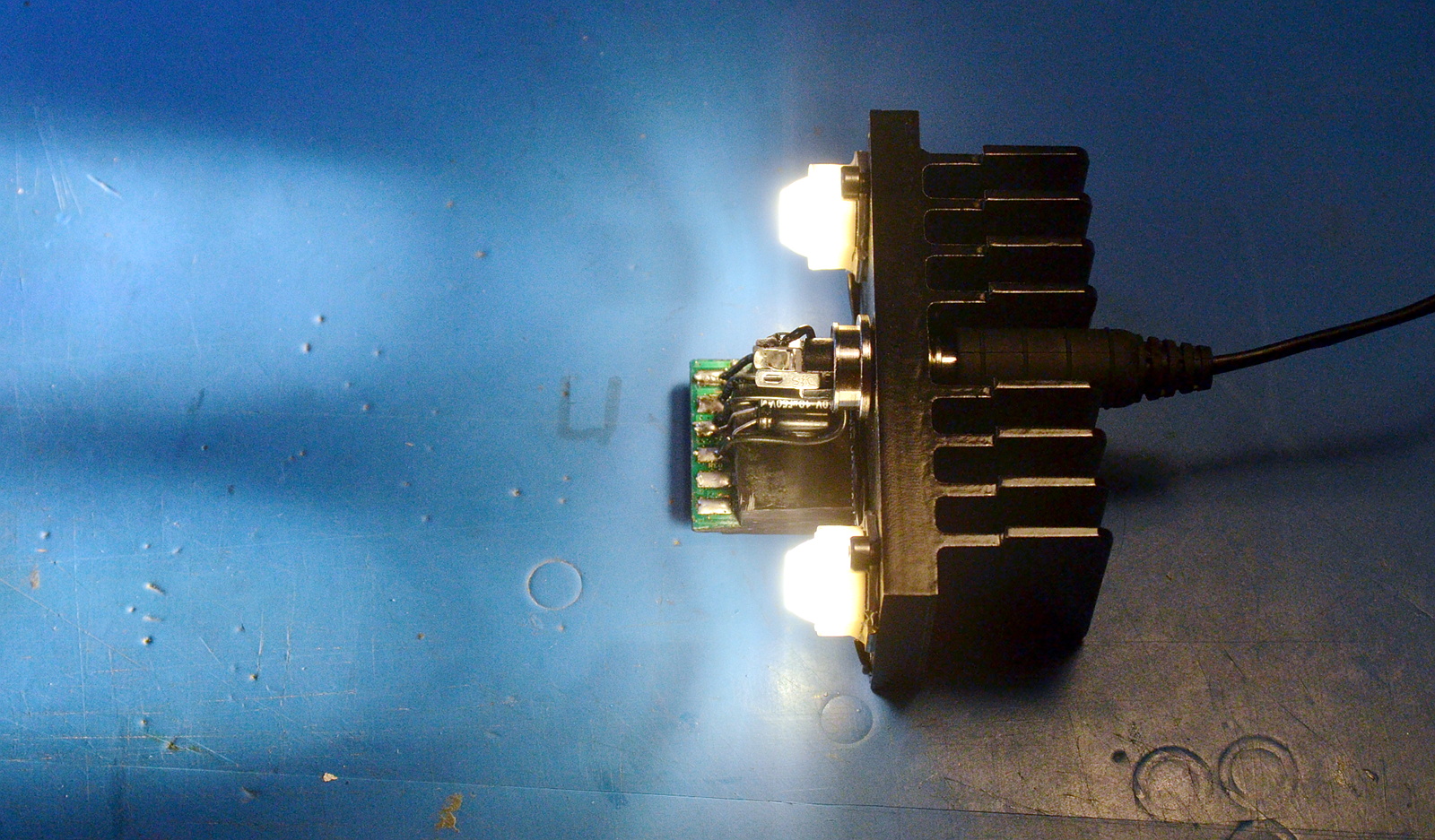

Noq2's approach works because of:

a) brute force: 60W of LED light is the

equivalent of around 350W of halogen light

b) a large die LED (7mm diameter!): that's more like a small COB

In his case it's a 'close enough' approximation to infinity focus

because of the huge die and tons of output. There's enough nearly

parallel light in there along with all the rest to make it work. Most

of the light that makes it into the optical path (which is likely only 5-10%, the beamsplitter doesn't combine much) is just lighting up the

inside of the microscope body, but the light that does make it all the

way through is diffuse and even and nice. Brute force works!

Me, I want as much of the light to be usable as I can get.

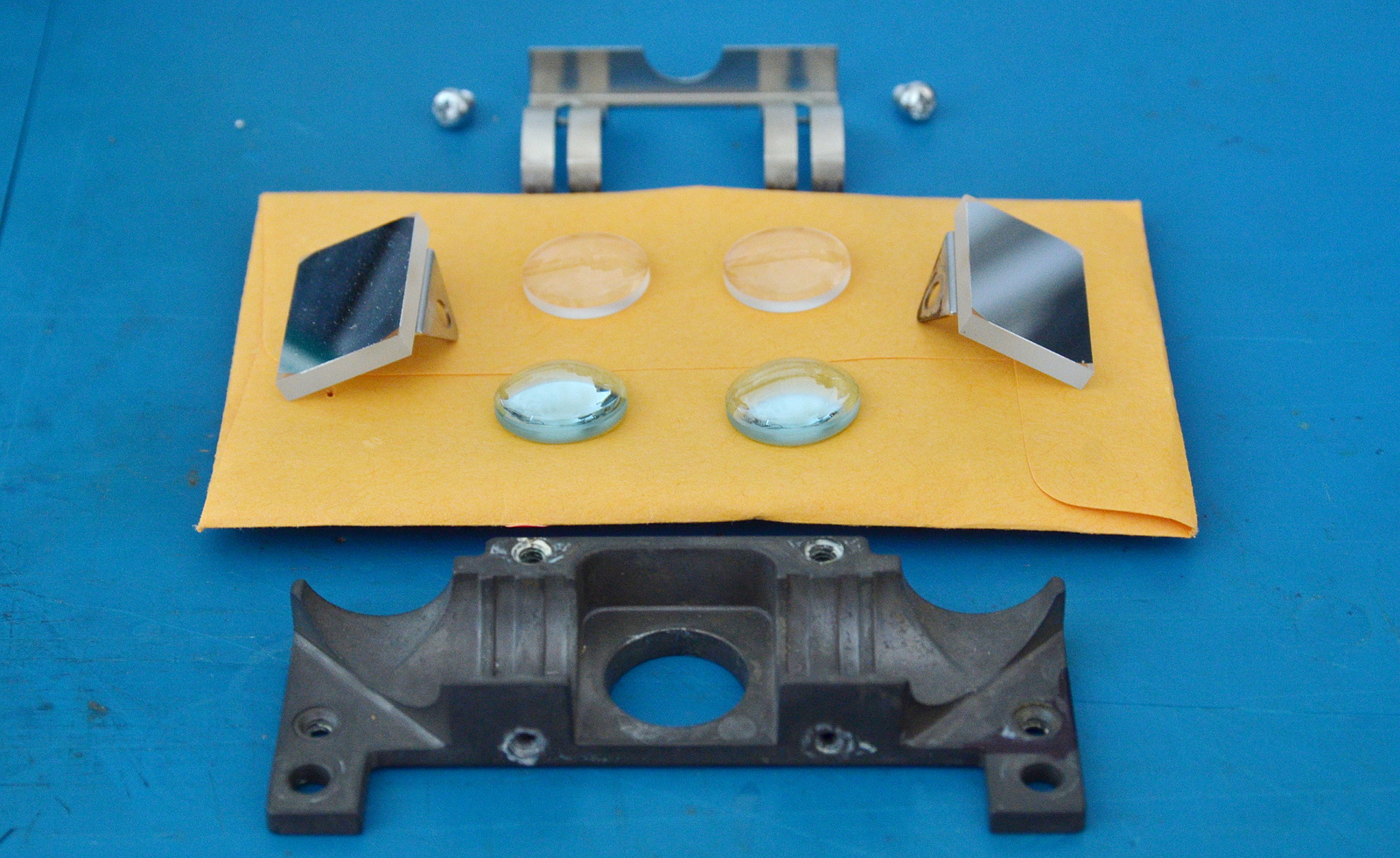

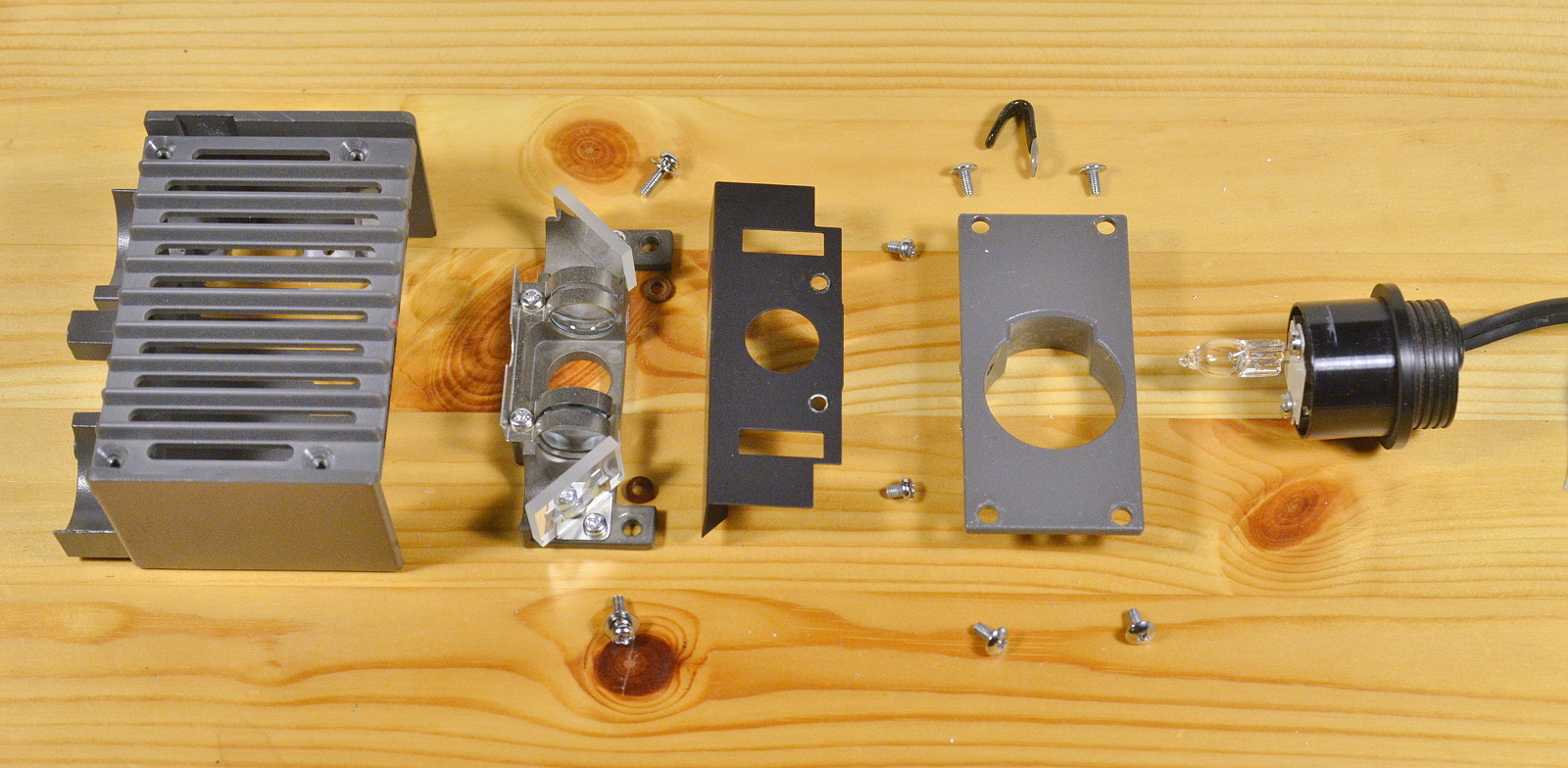

So I'm probably back to using lenses. The stock Olympus setup uses

two air-gapped elements with a total focal distance of 11-12mm placed

on either side of a halogen bulb. The bulb filament intentionally

sits just in front of the focal point to defocus the image slightly.

(EDIT: Actually, I'm wrong here; it's just past the focal point in order to produce a focused image of the bulb filament at the point of the iris in the microscope body).

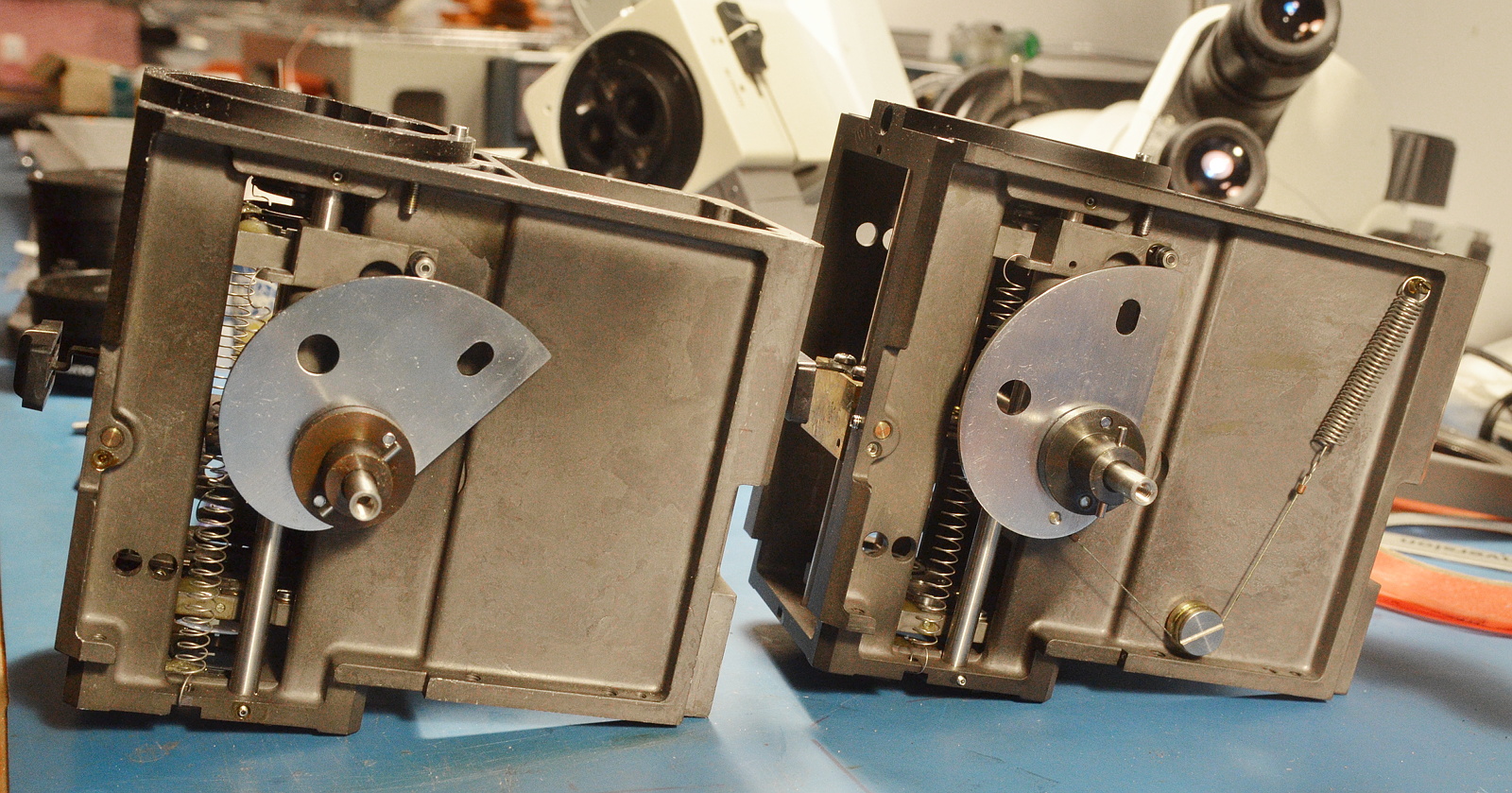

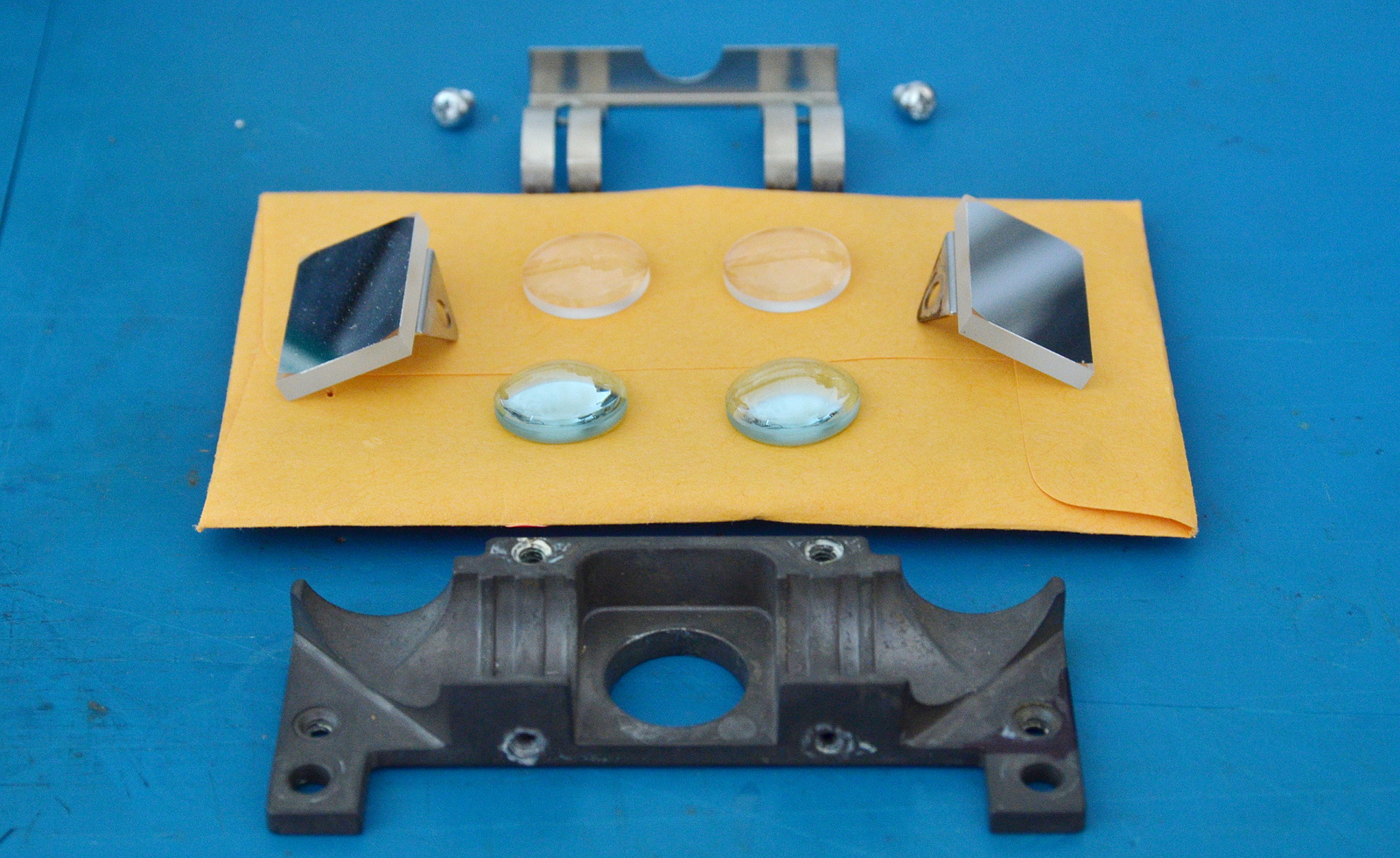

Olympus uses some really nice glass. The first

condenser element is a partial shortpass to filter out some of the

infrared. The second weaker element nearly touches the first and

finishes the collimation job. Two 45 degree front-surface (!) mirrors

direct the light into the beam combiner body.

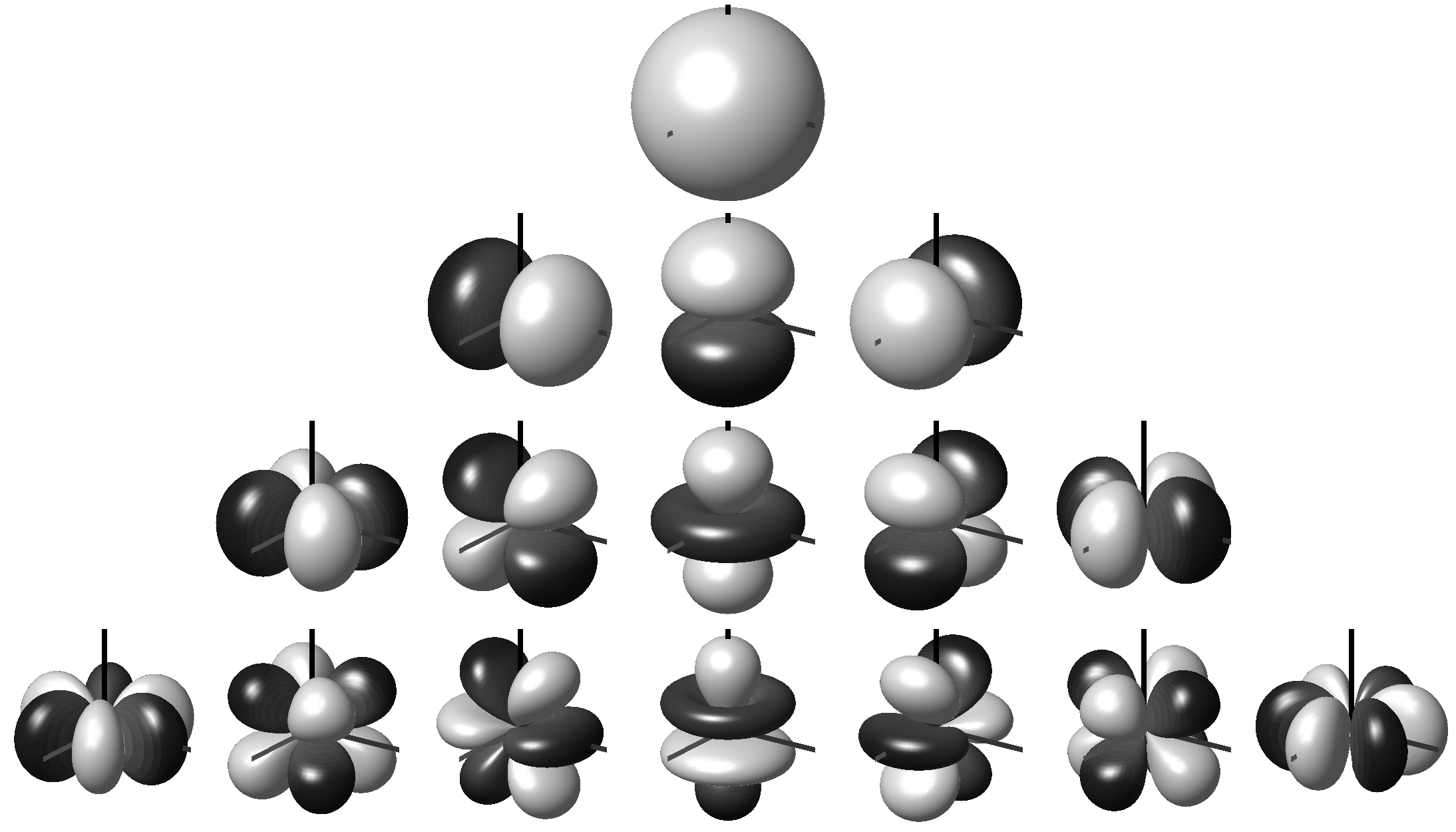

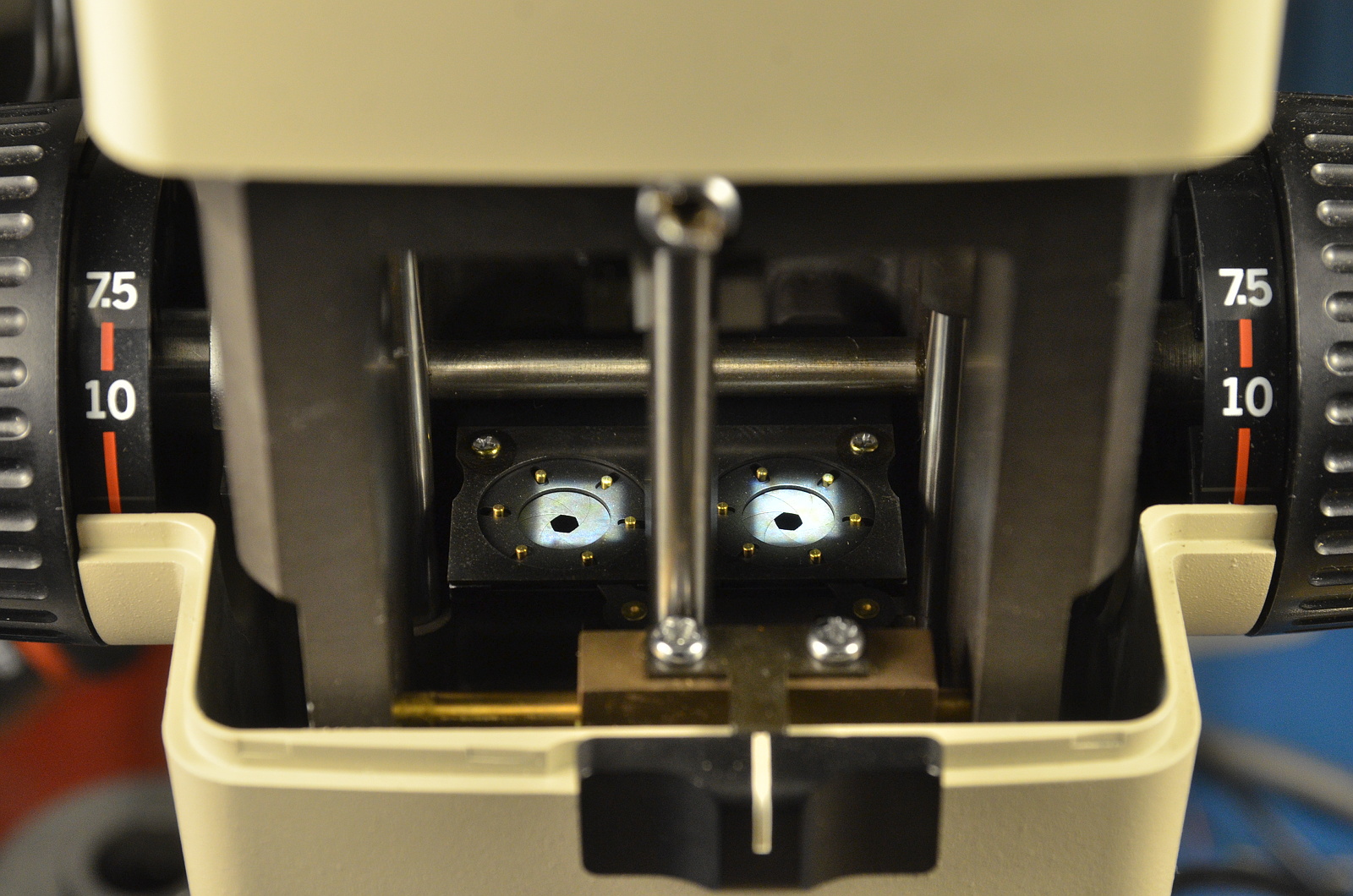

The biggest constraint on the collimater design is the diameter of the

optical path through the scope, which is a little under 15mm at

multiple points. Opposing that, we want to collect as much light as

possible from the LED into the condenser, which means putting the

lenses as close to the emitter as possible, and so choosing the

shortest practical focal length. Focal length trades off against beam

width; the shorter the focal length, the more the 'image' of the LED

die is magnified and the wider the final collimated light beam.

The original Olympus optical design expands the image of the halogen

bulb filament into a beam of approximately 15mm diameter, matching the

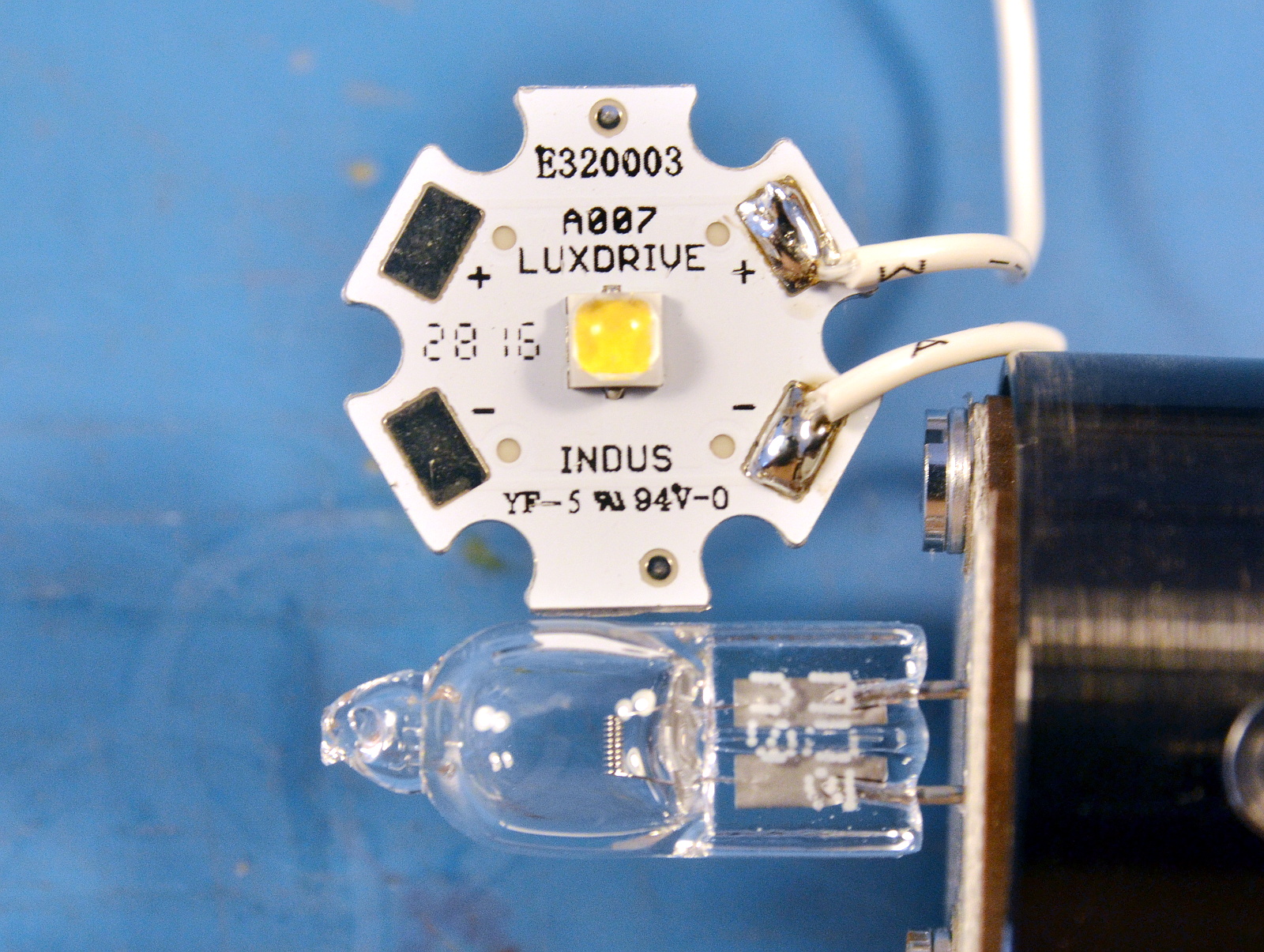

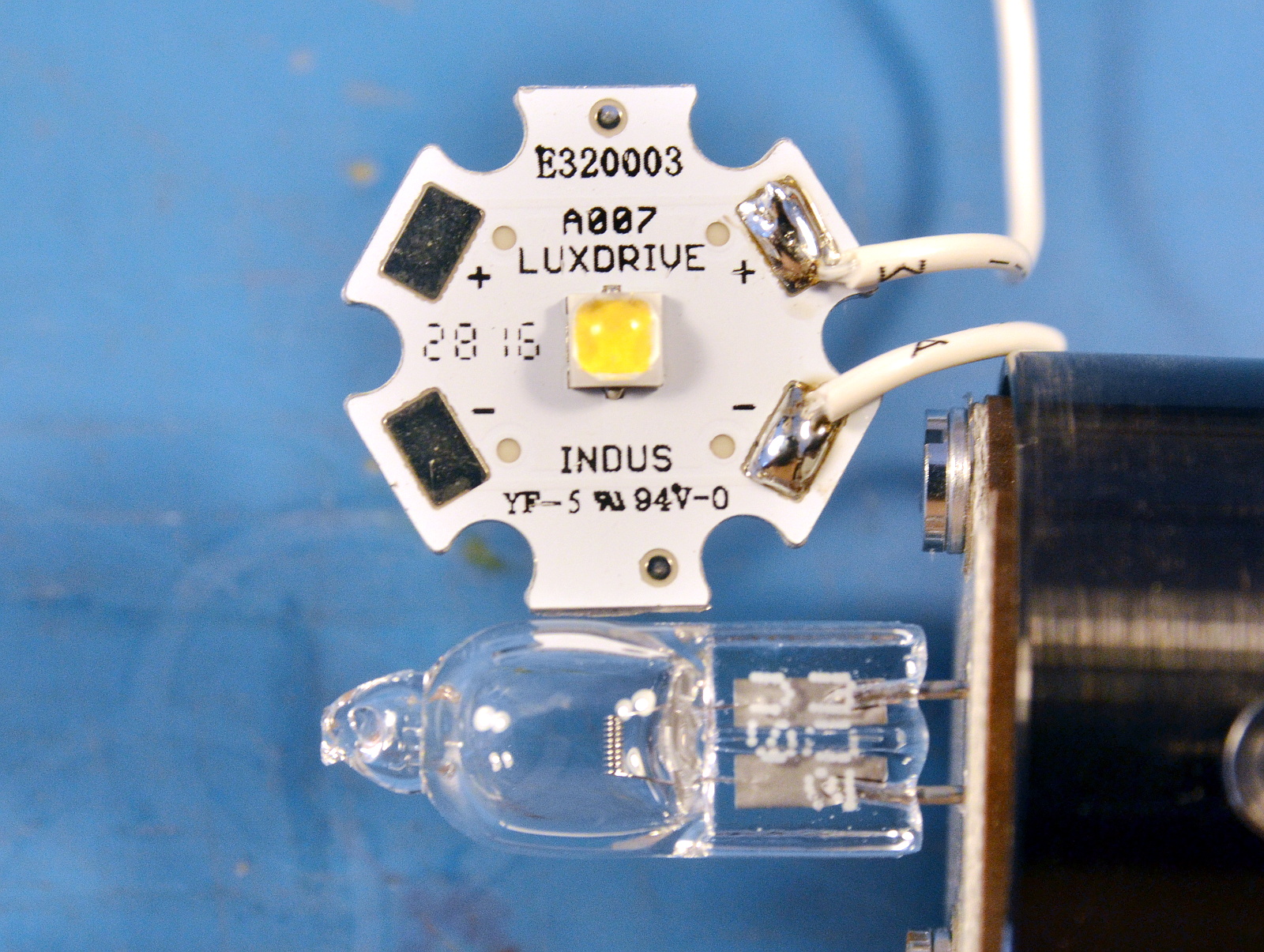

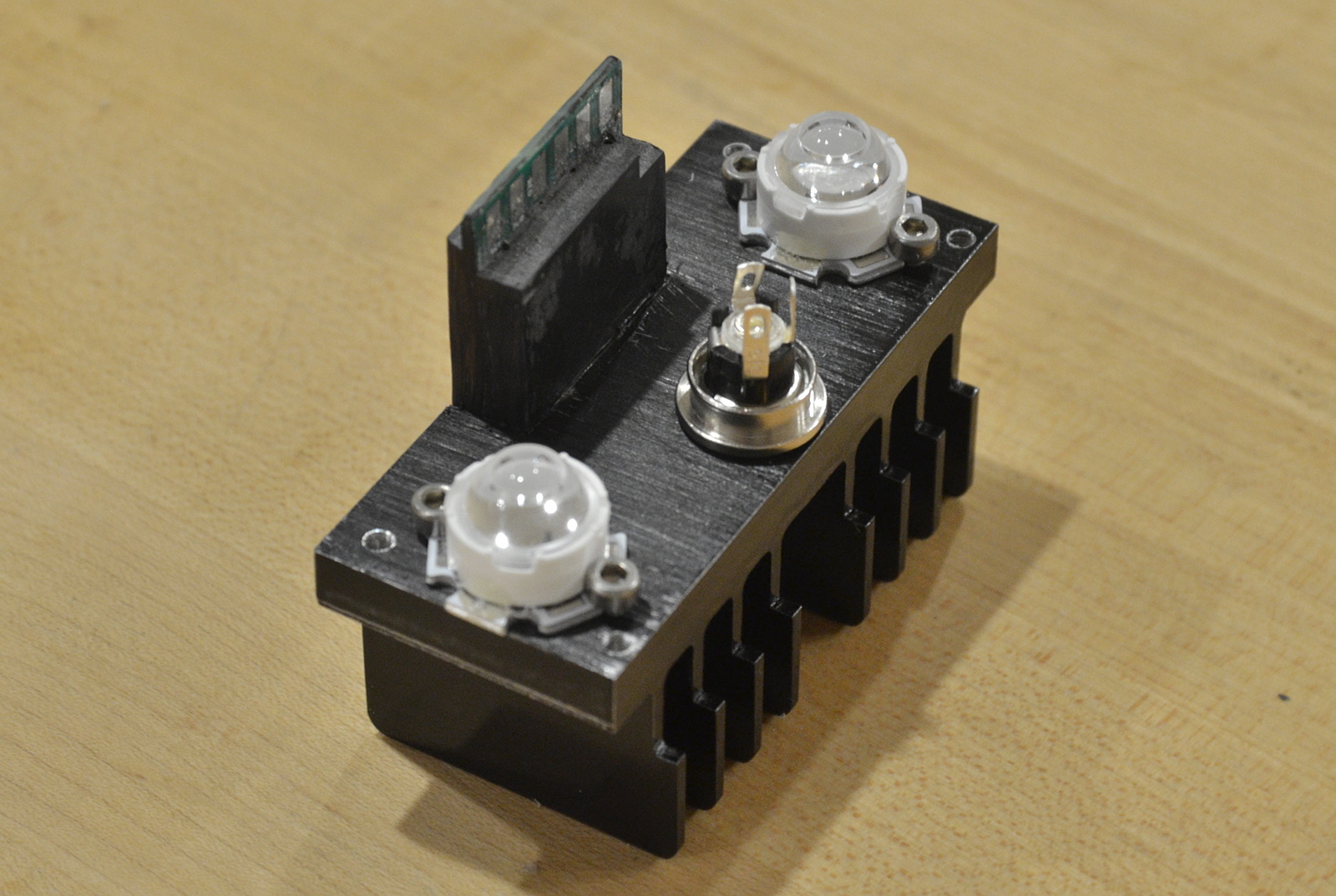

optical path. The Cree XP-L LEDs I'm using have a die almost the same

major dimension as the bulb filament.

A more powerful LED

with a bigger die probably isn't useful if we're going to use a

single-stage collimator. And an XP-L is easily the highest-flux

LED I can get with a die this small.

The XHP70.2 might put out 5x as much light, but if that's over 5x as

much area, it's not a net gain given the constraints (I'm

going to test it anyway, but I don't have high hopes). The big die of

the XHP70.2 isn't a problem for noq2 because he's not using any optics

that magnify its apparent size. He could usefully apply a 15mm COB.

This also means we're not going to improve on the original Olympus

lens choices without going to a more complex beam reduction design

that probably won't fit. (EDIT: Actually, I can probably fit a Keplerian design in there)

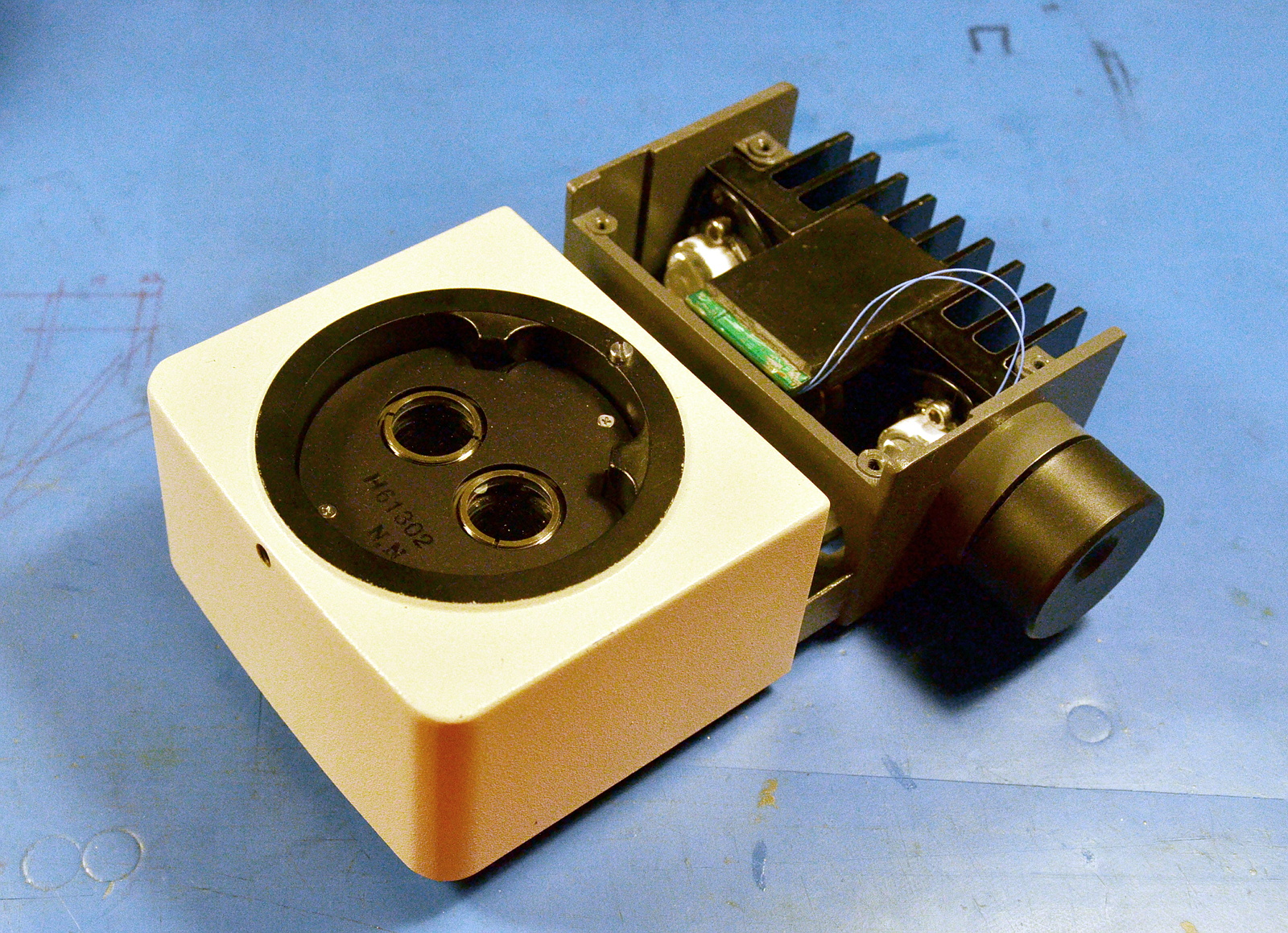

I'm going to try it Olympus's way. Given how dang nice those

lenses are, I'm totally yoinking them. And since I'm messing so

much with the physical layout, I want some adjustment ability. Which

means at this point-- I'm most of the way back to my original design.

Oh well. At least much of it is actually built and this has become an

iterative process. A little at a time rather than one fell swooooooop.

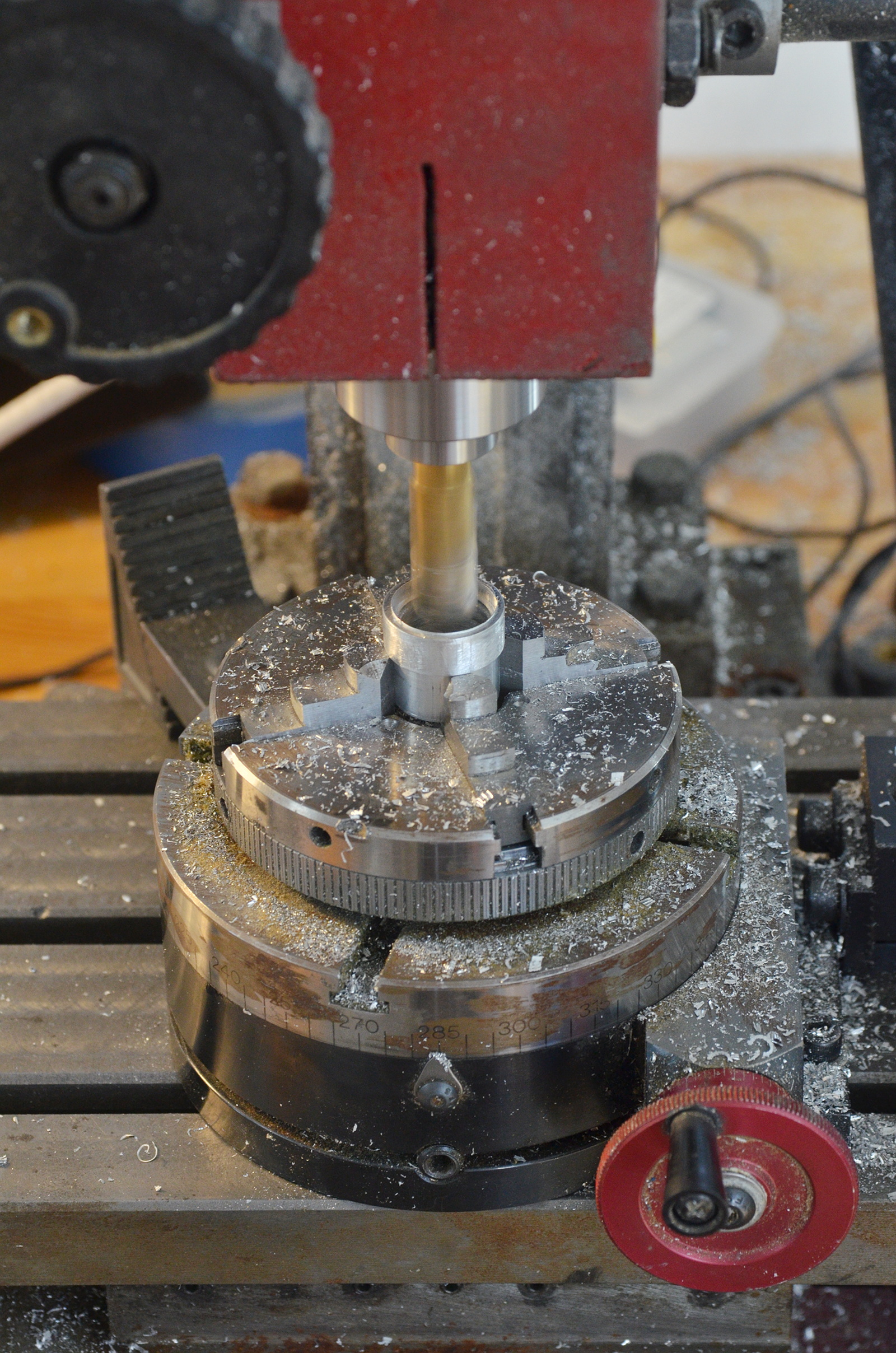

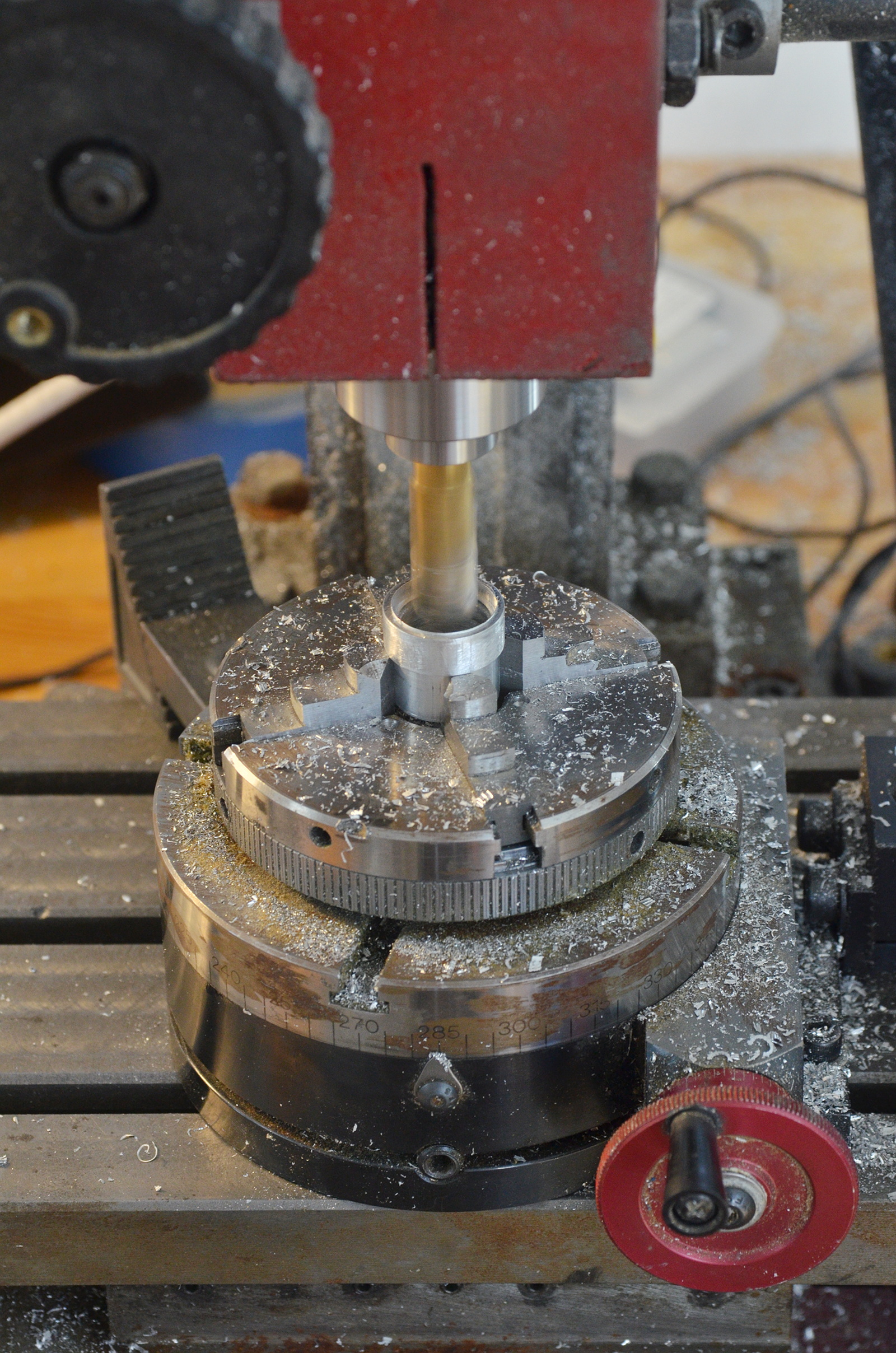

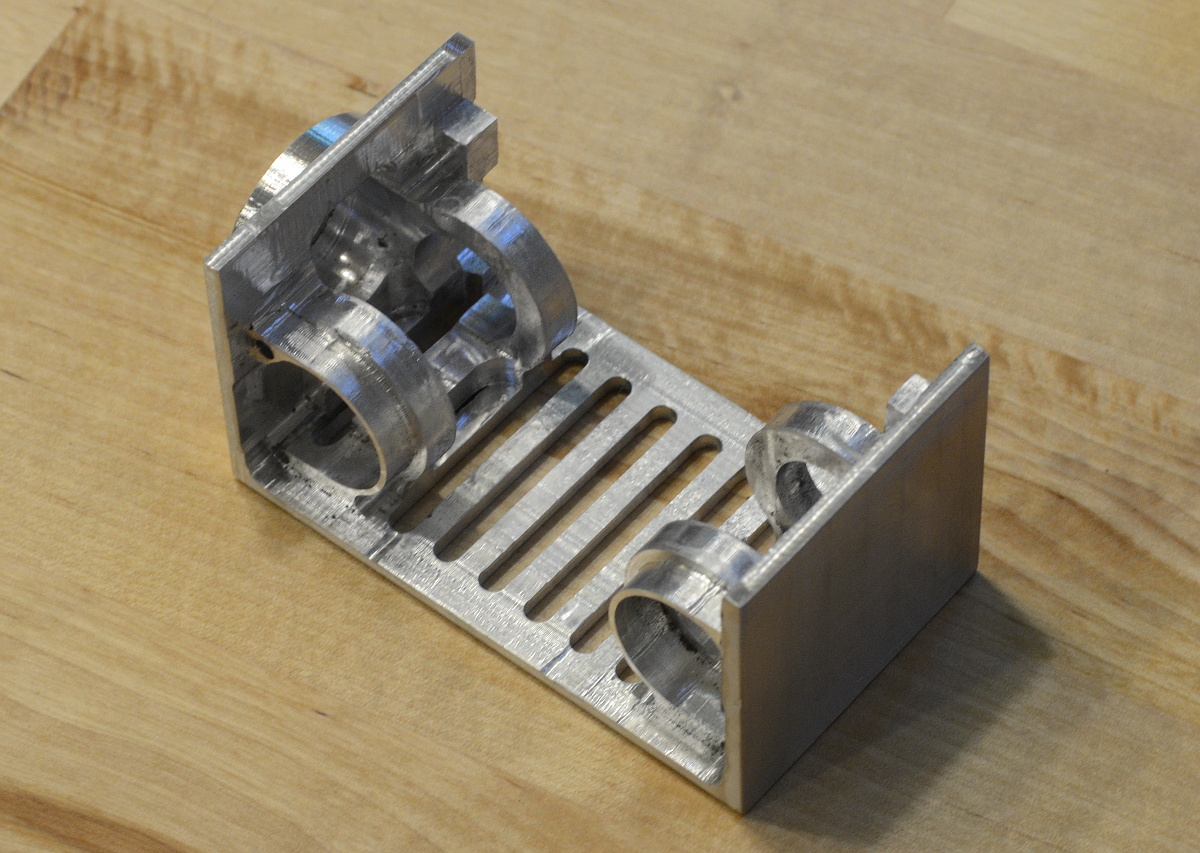

So... The next step is making some new lens tubes.

And mounting the Olympus lenses in them (using nice, reversible, not messy O-rings).

And mounting the Olympus lenses in them (using nice, reversible, not messy O-rings).

This gives me the lenses at the proper separation in a durable,

flexible package. Now I have to make a tube mount that fits inside

the lighting enclosure.

This gives me the lenses at the proper separation in a durable,

flexible package. Now I have to make a tube mount that fits inside

the lighting enclosure.

And mounting the Olympus lenses in them (using nice, reversible, not messy O-rings).

And mounting the Olympus lenses in them (using nice, reversible, not messy O-rings).

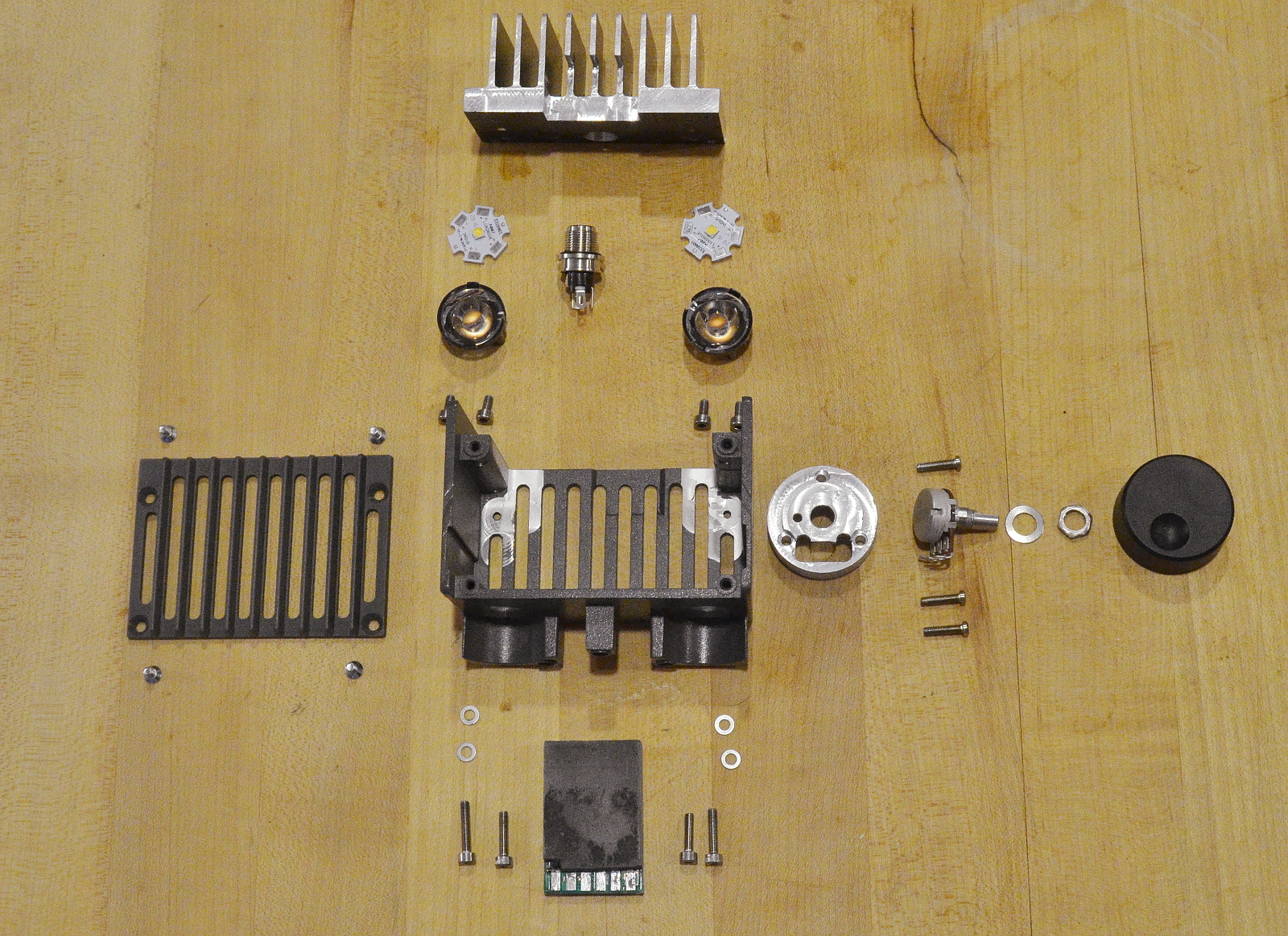

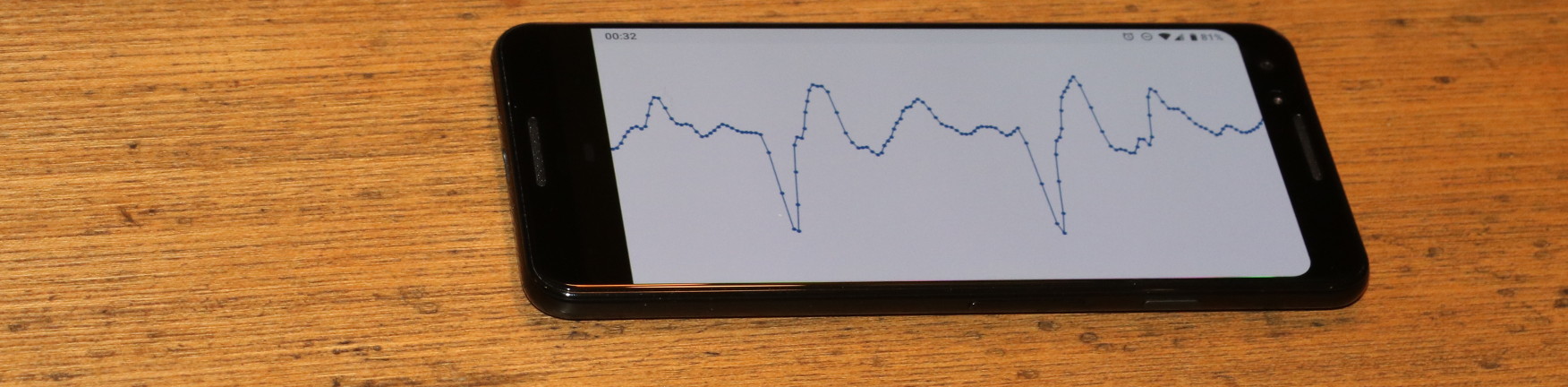

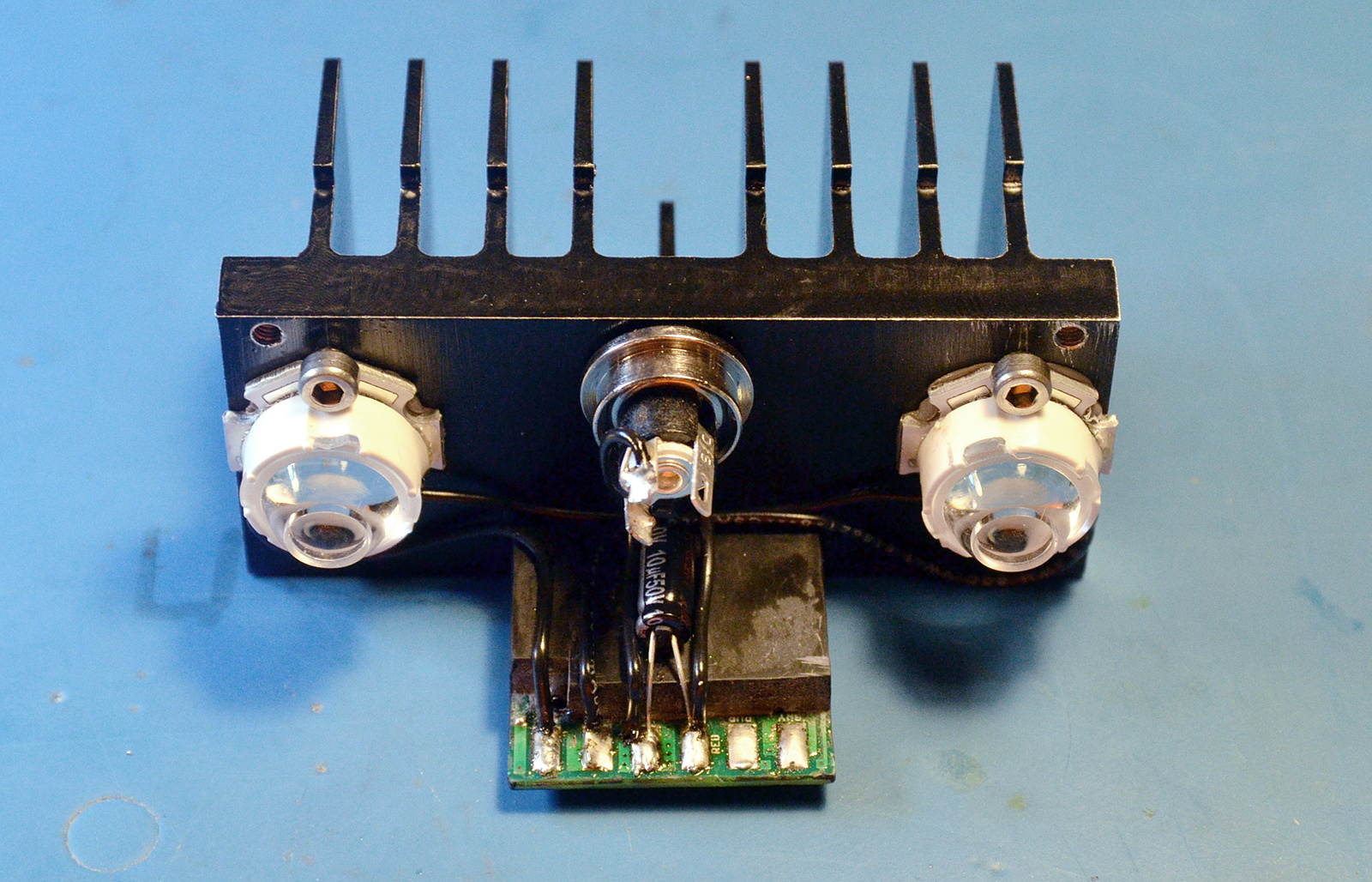

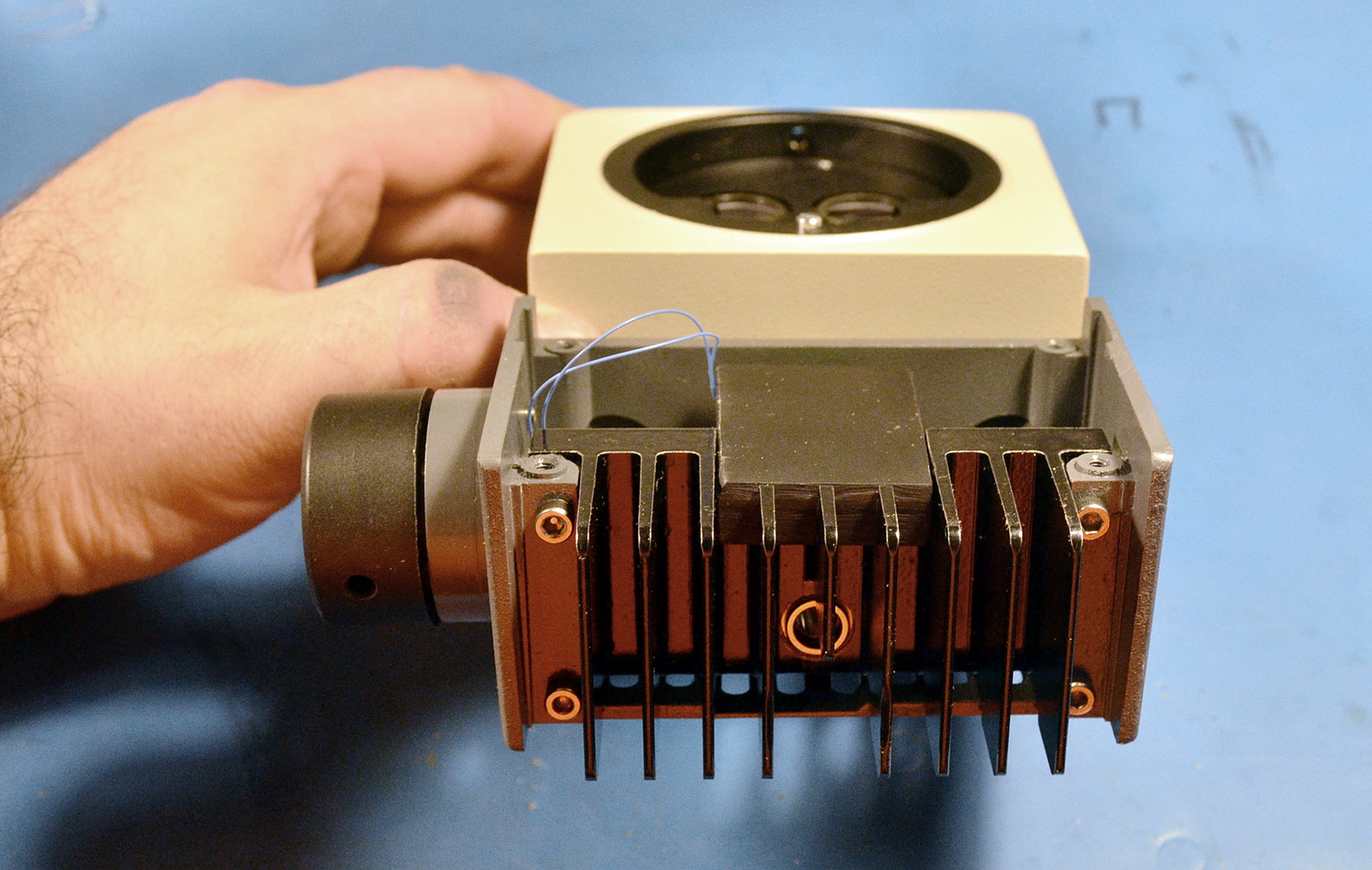

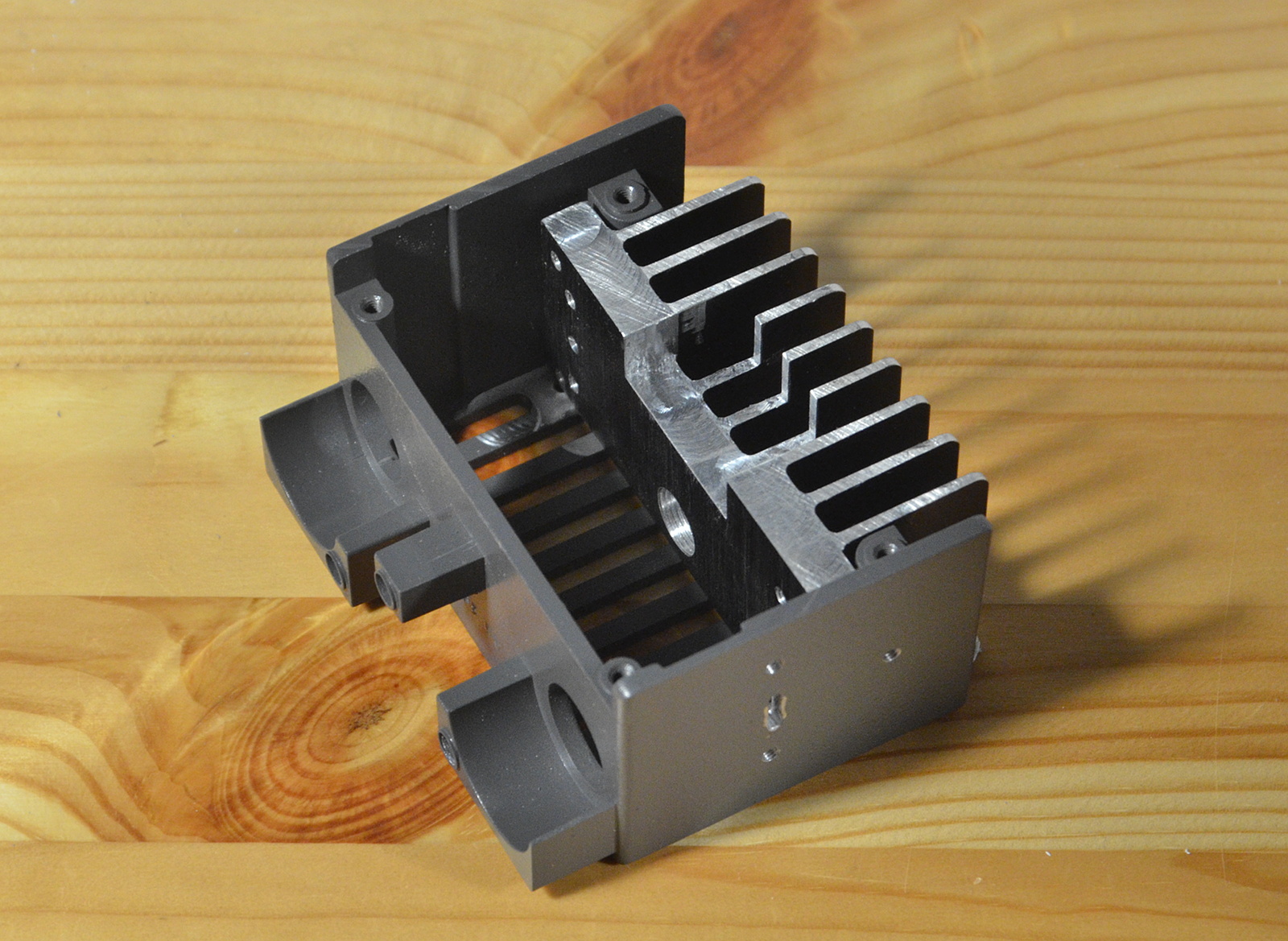

I want an intensity adjustment knob, so I stole the boss off the prototype I machined earlier this year. Along with bolts, a really nice 11-position-with-detents potentiometer, and

I want an intensity adjustment knob, so I stole the boss off the prototype I machined earlier this year. Along with bolts, a really nice 11-position-with-detents potentiometer, and