SZH coaxial illuminator LED mod: Part 2

Dec. 15th, 2018 10:17 pmAfter evaluating several different canned collimators, I chose the oddball Ledil Tina spots as having the best behavior when used with the illuminator head optics. They're stick-ons, so I stuck 'em on, and added a few tacks of UV-cure resin as well.

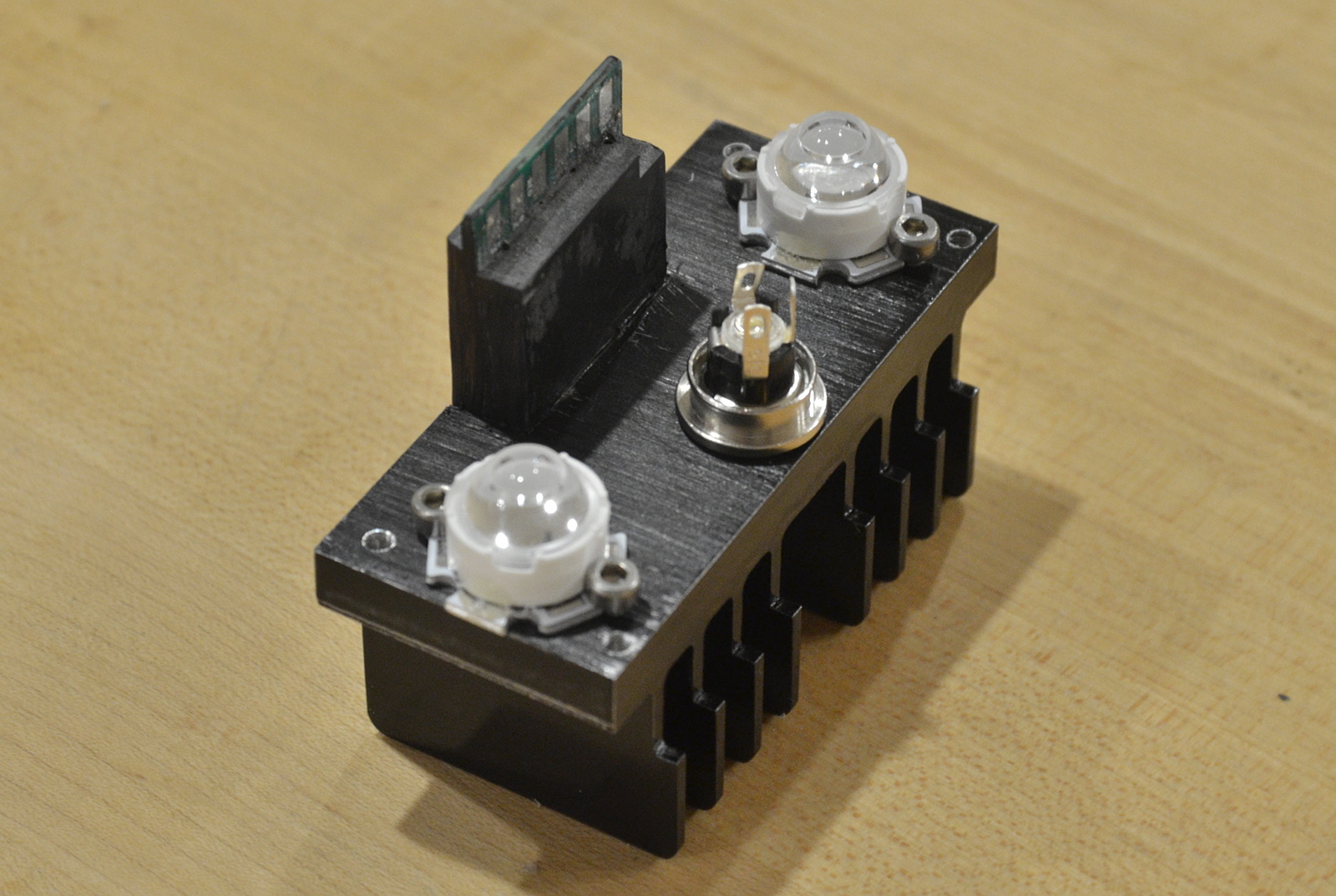

Inital heatsink assembly with LEDs, DC jack and BuckBlock looks good!

The intensity adjustment on the BuckBlock is voltage controlled and sources 500uA; the data sheet suggests feeding it through a 20k potentiometer to ground. That has two [minor] problems.

I'm using a pot with detents, and the way the adjustment curve goes, I'd end up with dead notches at both ends of the adjustment range. Second, the adjustment curve is linear and it would be nice to have more resolution in the low range. Intensity perception is exponential.

The first problem could be solved by using a 15k pot and adding a fixed 3k resistor at the lower end. The second problem is usually solved by using a log-taper pot (or in this case, I'd need an exponential, so I'd hook it up 'backward'). The problem is no one makes log-taper 15k pots, and certainly none with detents. Also, I already have linear-taper 11-detent 10k pots, and I don't feel like wasting them.

The usual trick of turning a linear-taper pot into a log taper with an extra resistor doesn't work here. I need an exponential taper, not a log taper. This is where older tinkerers usually start whipping out transistor circuits, and the more recent crowd embeds an entire microcontroller and writes software to get the desired curve.

I'll admit I played with a transistor circuit for a little while but my pots turn out to have a third problem-- the first and last steps are 1/5th the step size of the middle eight. That's when I realized I didn't want to work around a suboptimal part. The right part makes all these complications go away, and I can have the right part.

These pots are just carbon-element-on-phenolic-inna-can. So I pried the can open, and scraped the resistance element into the resistance and curve I wanted with a hobby knife. I cut the last step into an open (which will cause the adjustment's current source to float up to full-range), and trimmed the first step down to give a bigger step.

Now I have a the right part: a 15k pot that goes exactly to full-range in increasing steps. No additional electronics.

Today's work is done: I need to let the silicone holding the BuckBlock in place cure and the paint on the adjustment boss dry. Tomorrow I wire it up and test the assembled electronics.