Summary: Most 'new' HV121P01-100 SXGA+ screens for sale on ebay, AliExpress, etc, are neither genuine nor new.

Long version:

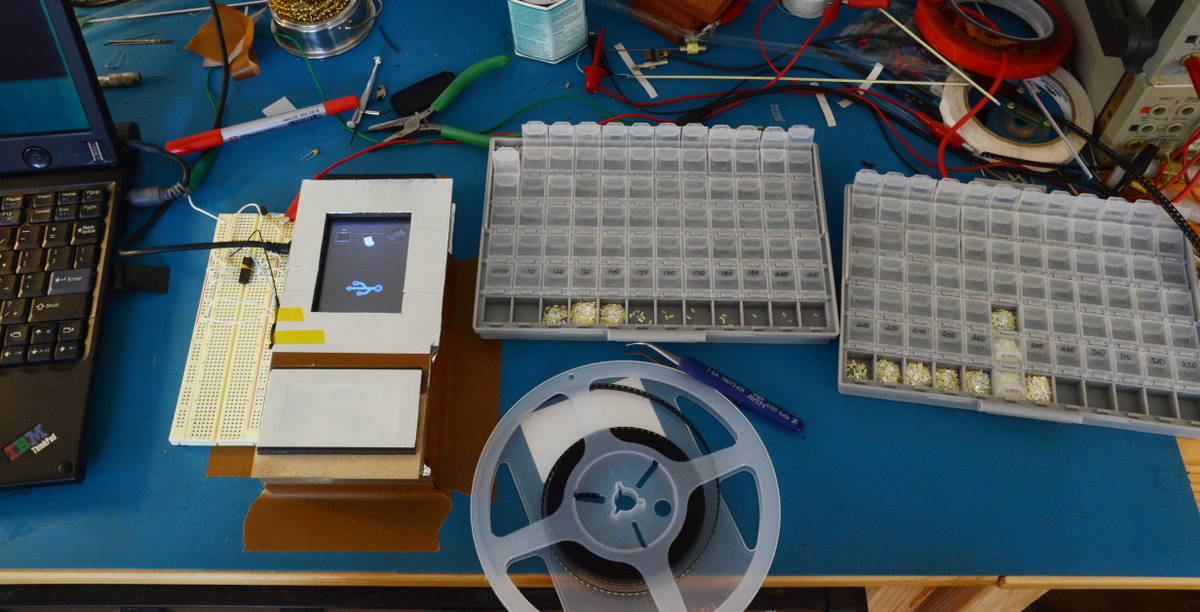

The HV121P01-100 is the screen every X60/61/62 ThinkPad modder wants.

It's a reasonably high-resolution AFFS (IPS-like) screen originally

offered as an option on the X60 tablet, and with a Daylight LED kit,

it has excellent brightness and good (though not excellent) color

accuracy. They're commonly available on eBay, Alibaba, DHgate, etc.

Except they're not.

A slightly later version of the screen, the HV121P01-101, was an

option on the X61 tablet, but it had a fatal flaw. Unlike the earlier

version, the -101 was bonded to a glass front-surface using a

'permanent' optical adhesive. This adhesive was not in fact very

permanent. It flowed when it got warm, leaving bubbles behind the

glass, and a sticky, impenetrable goo all over everything.

Ever get pine sap all over your hands and try to clean it off? Same

thing. No really; the optical adhesive is a purified pine tar.

Mmm, I do love that Christmas tree smell.

In any case, the HV121P01-101 turned out to be a warranty disaster and

there were tons of these screens left over that no one could use.

A few modders got reasonably good at removing the front glass and

adhesive through sheer force of will and infinite effort. This

task is seriously involved. I tried it. I wasn't patient enough

to get better than about a 50% success rate and it sure wasn't worth

the time--- especially when you could just buy a -100 version of the

screen without the problem.

These days, there are no more cheap -100 screens. Enter Chinese

entrepreneurs and a large quantity of similar, unsold -101 screens.

Rather than spending hours of careful mechanical work removing the

glass fronts and adhesive from the -101 screens, you can just dump the

screens into a big vat of hot solvent. Of the solvents I've tried,

xylene is cheap and works well. The solvent dissolves all the

adhesive away over a few days, and the glass falls right off. No

fuss!

This would be a brilliant solution except for one problem: it messes up the front polarizer film that's also bonded to

the glass LCD matrix.

Good polarizers cost more to produce than the glass LCD matrix

itself. BOE/Hydis used very nice polarizers on these

screens. Removing the adhesive with heat/solvents damages this expensive polarizer.

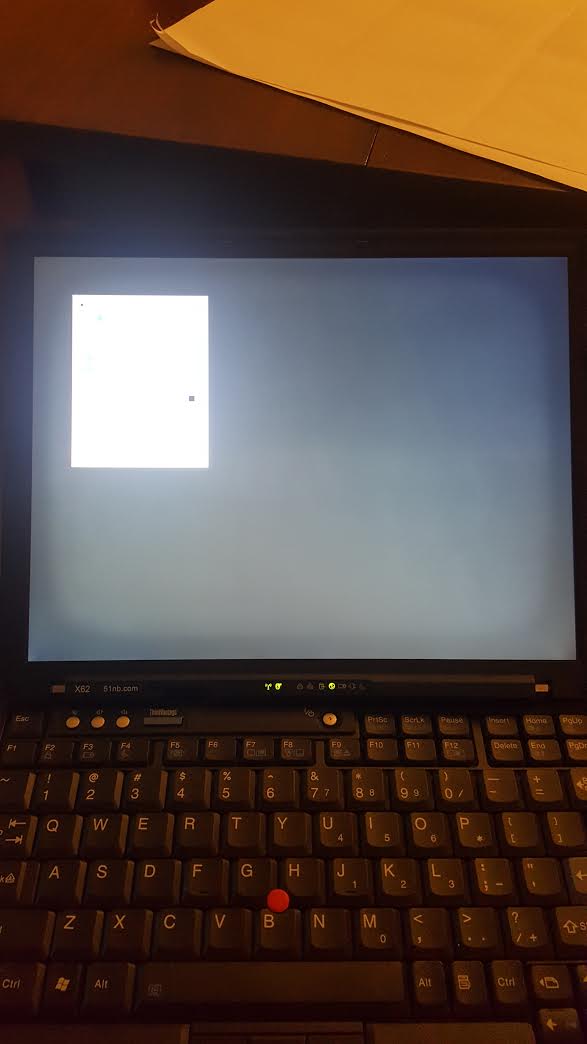

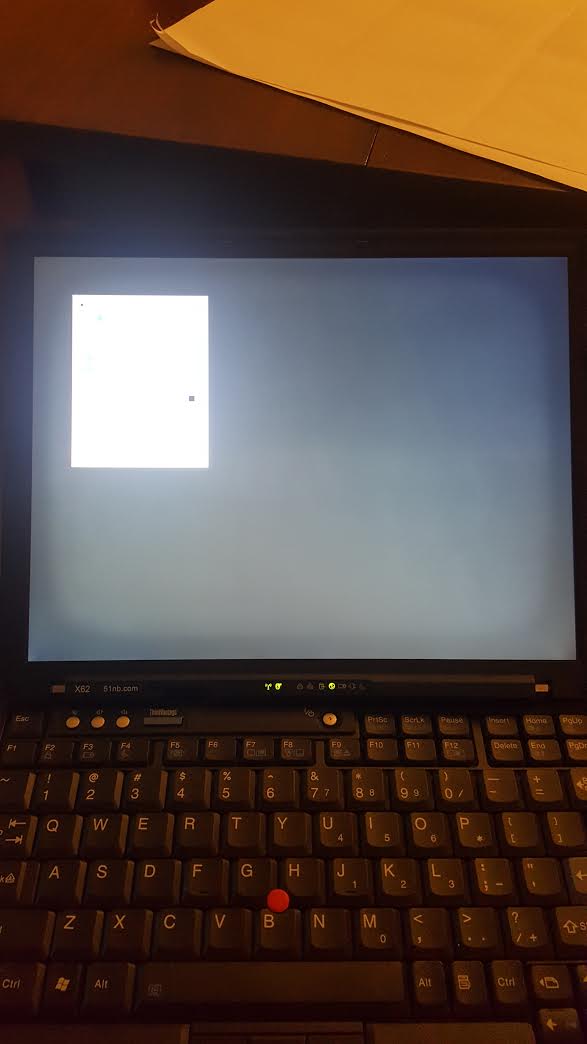

The damage looks a little like a kind of 'old-timey picture-tube' filter:

The above screen was being fed vertical lines for whatever reason, it's the ring of discoloration around the edge I'm talking about. Below is a more subtly damaged screen that wasn't obvious until the backlight got replaced:

Depending on the exact process, the damage can be subtle or obvious.

If the damage isn't 'too bad', the screen is just

sold as is, and these screens are definitely out there in the wild (see above). I know

a few people who didn't notice (or weren't bothered by it) until

installing a brighter backlight that made it more obvious. That's how I got the pics (thanks guys!).

When the polarizer damage is too obvious, the screen rebuilder can strip off

the damaged polarizer film and install a new one. Like I said, the best

polarizers are really expensive, and I will say from personal experience

that these rebuilders are, in general, not using the best polarizers.

Cheap polarizers make for poor contrast, and cause color shifts at an

angle which kind-of negates the whole point of the fancy AFFS

screen.

Honest resellers are up-front when the polarizer has been

replaced, and the protective platic over the surface of the new

polarizer will still be there when the screen arrives. Maybe

you'll get lucky and it'll be a decent one. There's no way to tell

ahead of time, but I personally won't bet on it.

The less honest resellers won't tell you, or will claim the screen is

all new. Right now, this is also easy to spot!

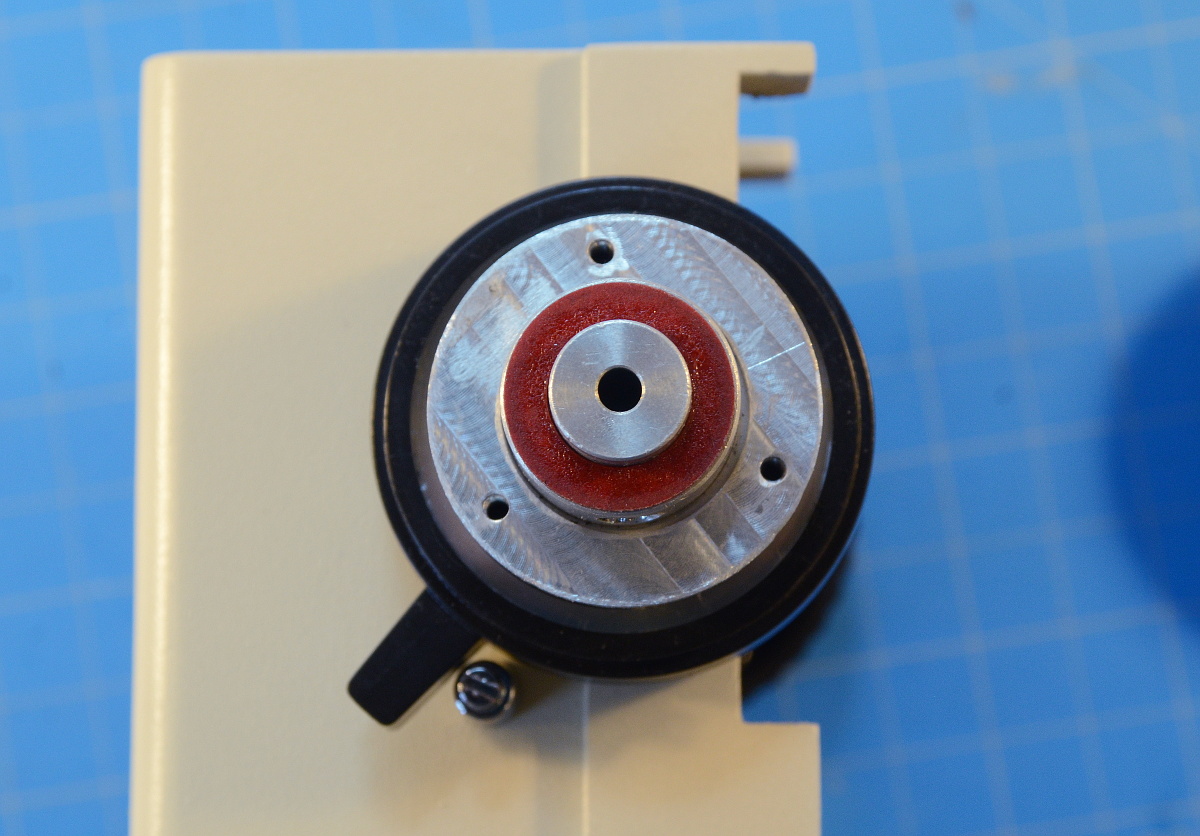

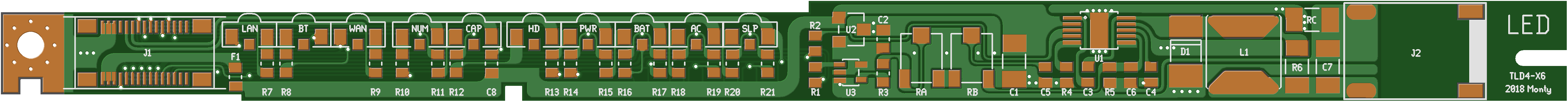

BOE/Hydis original

polarizers are always beveled at the corners:

Replacement polarizers are not:

I suppose dishonest rebuilders will eventually catch onto this trick

and begin beveling their edges too, but so far they haven't.

Oh, and it can get worse.

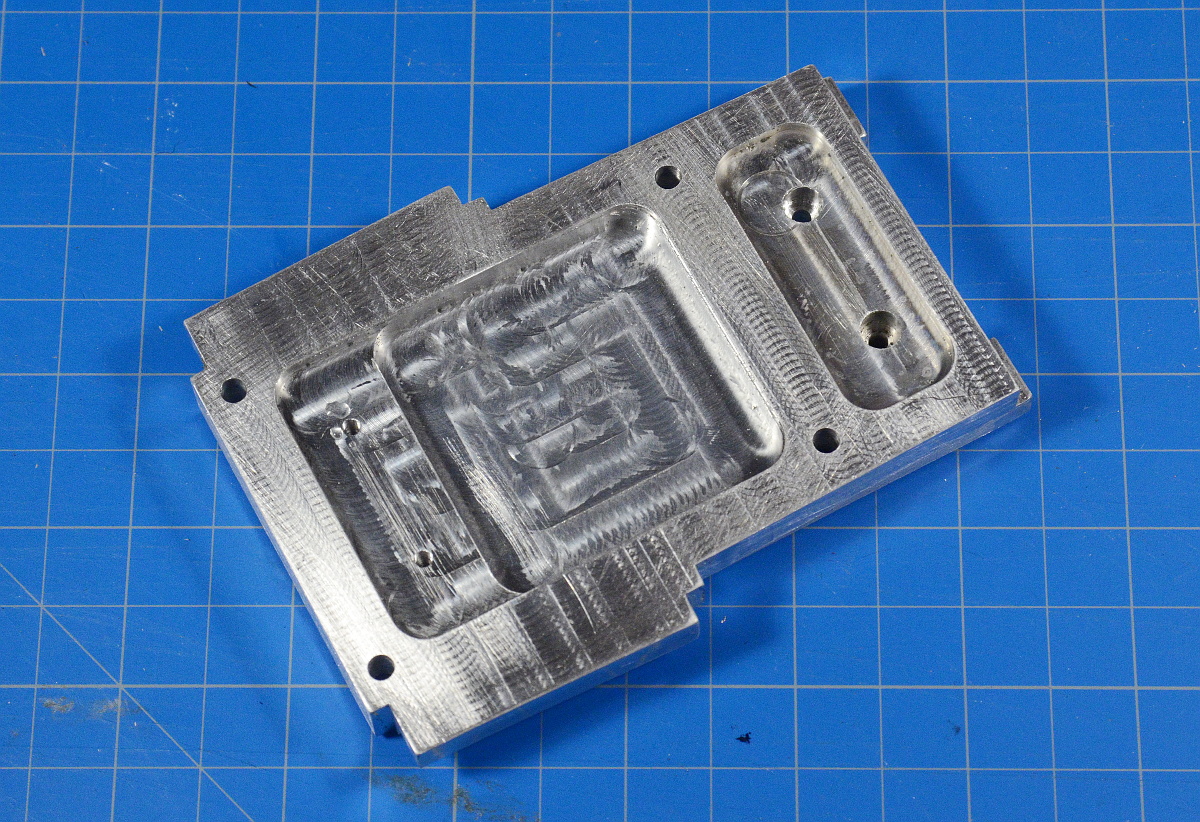

Solvents will also destroy most of the other components in the screen.

Some rebuilders carefully separate the parts and only dunk the glass

matrices, limiting the damage to the bonded polarizer. Others just

dunk the whole damned screen and let everything dissolve except for

the frame, electronics and matrix. These screens then have to be

built up entirely from spare parts.

In short, many of the HV121P01-100 screens you see for sale *don't

have a single HV121P01-100 part in them*.

Those stickers that say 'HV121P01-100'? Fake, altered, or transferred

from other screens. That closeup of 'HV121P01' stamped into the front

frame? Note that it doesn't say '-100' or '-101'.

Conclusion:

Do these rebuilt screens work? Yes. The problem is that many aren't

going to be anywhere close to the original performance specs. The

contrast will be lower, the brightness low/uneven, the colors poor or

unstable, at least relative to the original screen, which was no

performance monster to begin with.

Is that still worth ~ $100? You might say yes! The important thing

is to know what you're getting and be able to make an informed

decision. Otherwise you're playing a lottery and trusting the

ticket-seller to tell you if you've won.

Of course, you might get lucky and get a real -100! If you do, let me

know, I've not seen one in years, and I'd really like to know where I

can get some.

So how do I find a real HV121P01-100?

No guarantees, but look for a few things.

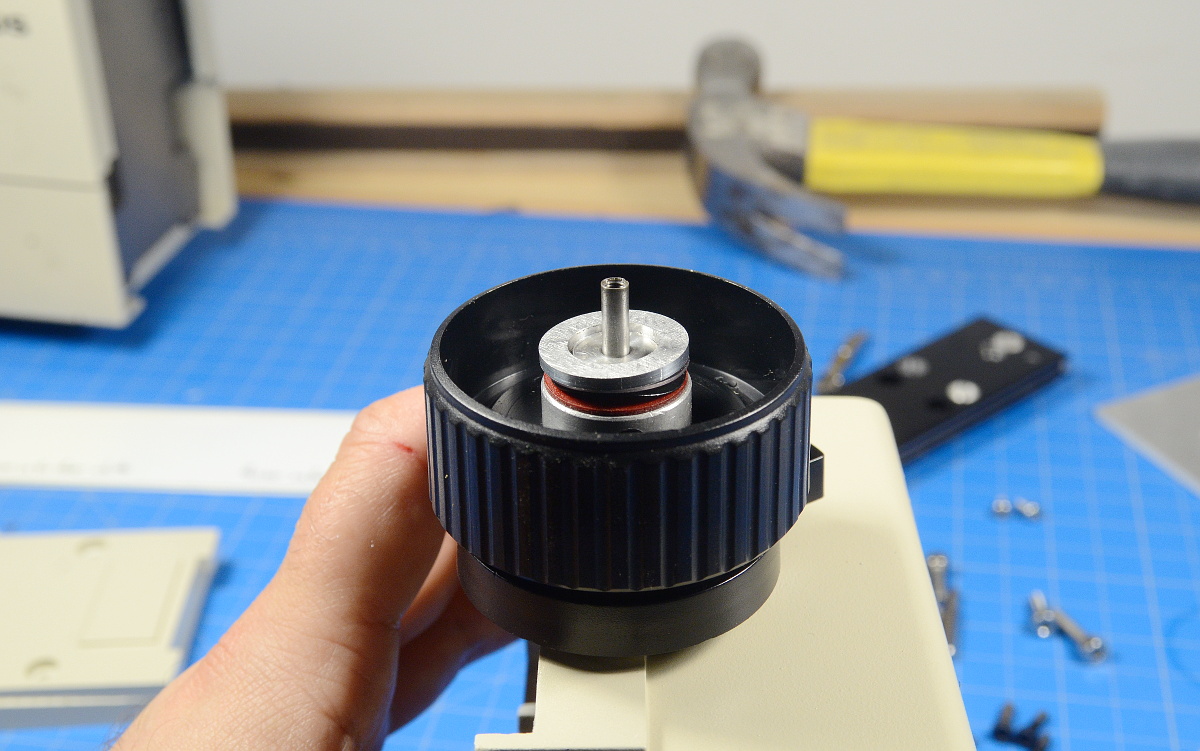

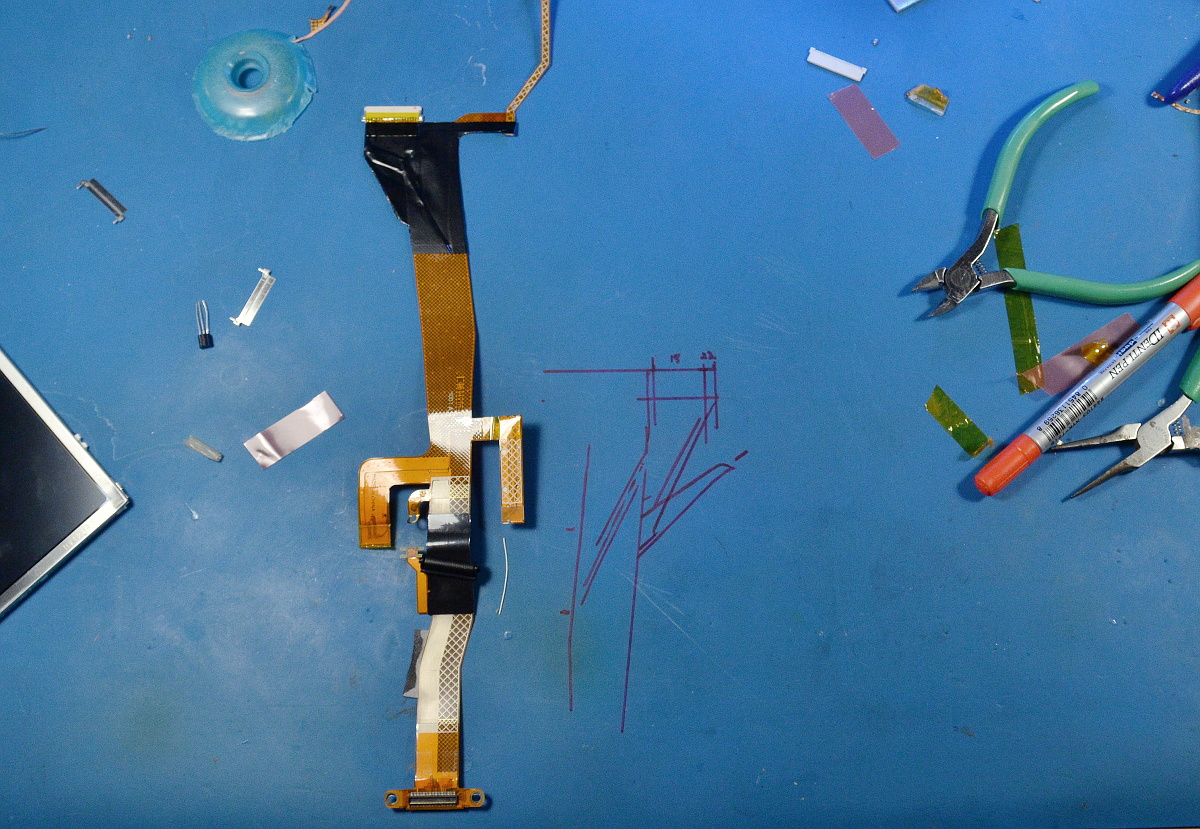

- Is the front 'glass' (acrylic on a real -100) still in place?

- Is the original digitizer still on the back? It's the rust-and-green flexy circuit board that provides the pen input on the tablet screen.

- Does the screen still have its tablet-mounting tabs?

- Is any of the frame tape cut, or are the internal diffuser film clips mysteriously missing (probably because the replacement diffuser films don't actually fit properly)?

- Is the listing using a stock pic (with a custom watermark) used by ten other resellers? Bad sign.

Not to pick on this specific seller (I doubt they know much about what they're selling), but here's a pic that hits almost all of the red flags all in one ad:

The digitizer is missing, the front acrylic is missing, the clips

that hold the internal diffuser films in place are missing, the sealing

tape along the bottom of the frame is cut, and the plastic cover with

the 'HV121P01-100' sticker and serial number has obviously been

transferred from another screen. Best of all, this is a stock pic, or

rather, the exact pic is being used by 6 or 7 eBay sellers right now.

They care so little about their listing, they're using a pic of a

screen that's obviously been rebuilt from parts, not even trying to hide it, and

the screen is listed as 'new'.

WELL DONE. I TOTALLY TRUST YOU.

In any case, the best way to screen out sellers is probably just to contact the seller up front and ask specific questions. Most are just resellers, and have no idea what they're selling, but you can at least ask for pics of an actual screen for sale. Any evasion from the seller is a pretty good indication you should walk away.

Hmmm... George is squinting in each picture. I wonder if he needs glasses already.

Hmmm... George is squinting in each picture. I wonder if he needs glasses already.